Technologies for special pasta shapes production

With a view to meet the continually increasing demands by the consumers most of the industrial pasta factories have paid more and more attention to the production of special pasta, which occupy e good portion in the market. All the production lines for short-cut pasta, long pasta and MULTIPLA version, are pre-arranged for the production of nest-shaped pasta thanks to a Nesting machine. Such kind of pasta can be obtained thanks to long pasta extruded directly from pasta die using Extruders fitted either with round or linear head (nests with flat, square, round or oval section) or by means of extruded or laminated sheet-pasta and Nesting machines equipped with calibration (smooth or rough) and cutting groups.

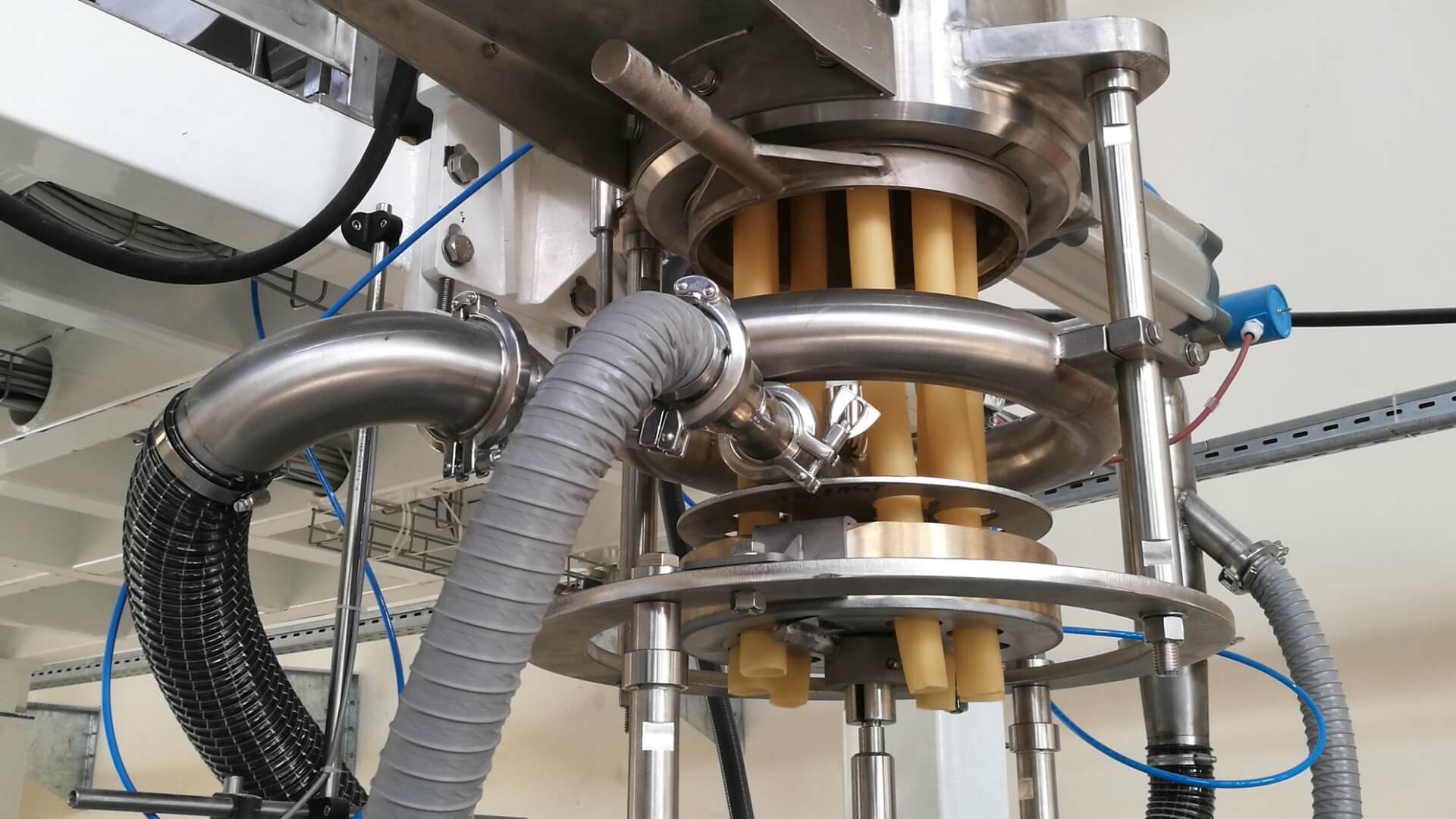

Number, shape and size of the moulding tubes can be customized. Nesting machines featuring single or double range of moulding tubes by different outputs are available.

Each machine is complete with Loom-feeder, PLC for management of parameters and speeds and is also pre-arranged for coupling with automatic Loom-stackers.

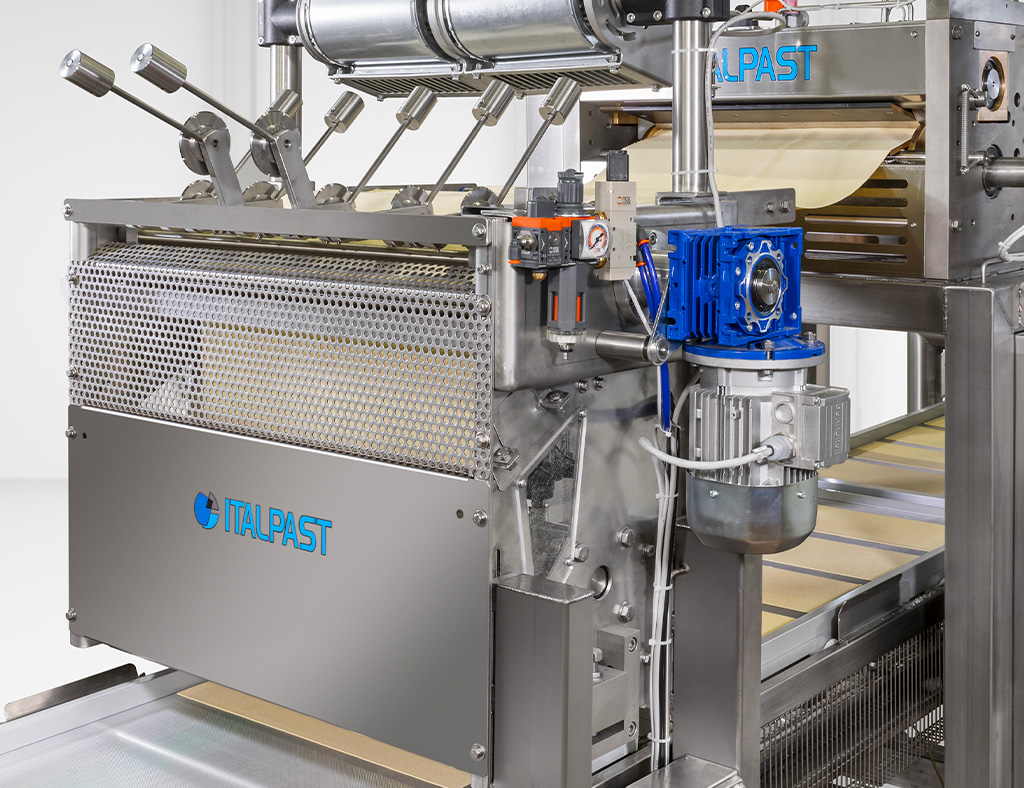

Lasagne can be obtained starting from extruded sheet-pasta or laminated pasta. The extruded sheet-pasta is produced by the Extruder thanks to the proper die whilst the laminated one is produced by a Sheeter, which received the dough either from the Extruder mixer or from a dedicated Mixer. The sheet-pasta is then laminated thanks to one or more calibration phases before being cut to measure and spread onto drying looms by a proper Lasagne machine, which can be independent or supplied coupled with a Nesting machine.

On request it is also possible to produce “matasse” and other special multilayer or coiled products.

The lines destined to the production of special shapes can be engineered ad customized depending on the users’ specific demands, thus ensuring higher production flexibility and swift return of the initial investment.

Thanks to specific cutting devices, besides the traditional pasta shapes, also cannelloni, “paccheri” and other large size shapes, e.g. “conchiglioni (big shells) and “lumaconi” (snail-shaped pasta), can be obtained. By means of complementary machines the production range can be increased thanks to production of long pasta automatically spread onto looms.

The special soup pasta shapes, such as “quadrucci”, also called “nouasser”, “frida”, “eperlevél”, “hilopites” are obtained thanks to dedicated machines that are part of traditional production lines.

The Cutting machine can be equipped with a wide range of cutting groups enabling to obtain pasta of different kinds and size.

A capacity up to 1000 kg/h of grated pasta, also called “tarhonya”, “trahana”, can be produced by means of suitable machines that can be coupled with Extruders: the different sizes of the product can be obtained by simply changing the sifters the machine is equipped with.

The lines destined to the production of special shapes can be engineered ad customized depending on the users’ specific demands, thus ensuring higher production flexibility and swift return of the initial investment.

Video delle nostre linee continue per nidi, lasagne e paste speciali

Catalogues

Pasta production LinesOther plants for dry pasta

Contact usAsk for an advice to our technical Experts to implement the most suitable line for your needs

HEADQUARTER

43036 Fidenza (PR) – Italia

REGISTERED OFFICE

43121 Parma – Italia